Written and provided by Andrew Kidd, Chair of the FTMA Frame and Truss National Safety Council

Forklifts are indispensable tools, especially in the frame and truss manufacturing industry.

However, their utility comes with significant risks if not managed properly. Every year, workplace incidents involving forklifts result in serious injuries, fatalities, and costly damage. Between 2017 and 2022, NSW recorded 1,538 forklift-related incidents

In Victoria alone, more than one worker every week is seriously injured after being struck by forklifts or falling forklift loads. Eight people have been killed in forklift-related incidents since 2019, including three pedestrians working near forklifts. Pedestrians also accounted for 65 of the 157 accepted claims in the past 12 months where the cause of injury was a forklift incident. Fines and undertakings totalling more than $2.4 million were imposed or accepted by the courts for 16 WorkSafe prosecutions involving forklifts.

In our workplaces forklift-related risks are serious and these incidents are mostly preventable with the right safety measures, training, and equipment maintenance systems in place.

In this edition of our Safety Matters, we focus on forklift safety – why it matters, common hazards, and practical steps to ensure a safe and secure working environment for operators and pedestrians alike. Whether you’re an employer, operator, or safety officer, understanding and implementing best practices is crucial for reducing risks and fostering a culture of safety. Read on to discover actionable insights and tools to make forklift operations safer and more efficient at your workplace.

Each state-based safety regulator has their guidance material on forklift safety which mostly covers the same considerations. In May 2024 WorkSafe Victoria released an updated guide to forklift safety in the workplace. This newly published guidance provides practical advice on the safe use and maintenance of forklifts and highlights the need to separate forklifts from people on the ground, the information in this guide is applicable in all states of Australia.

WorkSafe Victoria’s new Forklift Safety Guide.

Key Components of the Guidebook

1. Responsibilities of Stakeholders

The guide outlines the legal duties of various stakeholders under the OHS Act and Regulations, emphasizing collaboration to promote safety-

- Employers – Must provide a safe work environment, ensure employees hold appropriate licenses, and consult on safety-related changes.

- Self-Employed Individuals – Have a duty to prevent risks to themselves and others.

- Employees – Are responsible for their safety and must adhere to workplace safety protocols.

- Managers and Controllers – Must ensure the workplace and its access points are safe.

Consultation with employees and health and safety representatives (HSRs) is mandatory when introducing changes or addressing hazards.

2. Forklift Selection and Planning

Selecting the right forklift is critical to workplace safety. Factors to consider include-

- Load Requirements – Weight, type, and lifting height.

- Worksite Conditions – Indoor vs. outdoor use, aisle width, overhead obstructions, and ground stability.

- Operator Skills – Training and familiarity with specific forklift models.

The guide also advises conducting thorough assessments during the planning phase to determine if forklifts are the safest choice or if alternatives, like cranes, are more suitable. It stresses that second-hand forklifts must undergo rigorous inspections and maintenance before use.

3. Training and Competency

Operators must undergo appropriate training, including-

- Licensing – A high-risk work license (HRWL) is required.

- Familiarization Training – Covers the specific forklift model, its capacity, and attachments.

- Task-Specific Training – Includes traffic management plans, load handling procedures, and fault reporting.

Supervision is crucial, especially for trainees or vulnerable workers. Unlicensed operators must work under direct supervision by someone with an HRWL.

WorkSafe Victoria’s new Forklift Safety Guide.

4. Hazards and Risks

The guide identifies common forklift-related hazards and their causes-

- Collisions with Pedestrians – Often due to shared spaces or limited visibility.

- Collisions with Other Mobile Plant – Resulting from poor traffic management or obstructed views.

- Instability and Overturning – Caused by sharp turns, uneven terrain, overloading, or improper use of attachments.

- Operator Ejection – Linked to the absence or misuse of seatbelts and protective devices.

- Falling Objects – Occurs when palletized goods are improperly secured.

Environmental factors, such as weather conditions and fumes from indoor operations, also pose risks.

5. Risk Controls

A major focus of the guide is on applying the Hierarchy of Control-

- Eliminate Risks – Remove forklifts from the workplace where possible.

- Reduce Risks through Substitution, Isolation, or Engineering Controls –

- Substituting forklifts with safer equipment like overhead cranes.

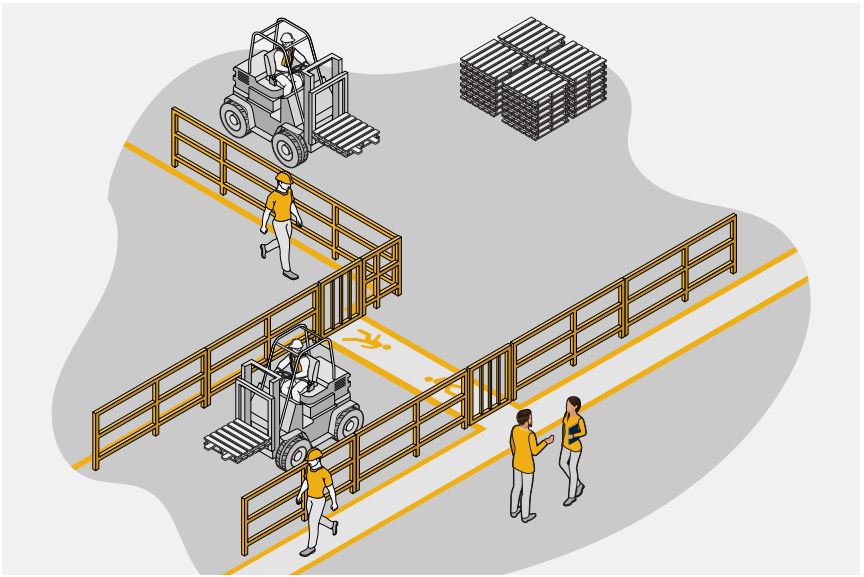

- Using physical barriers, exclusion zones, or warning lights to isolate hazards.

- Implementing safety features like pedestrian detection systems and speed limiters.

- Administrative Controls – Develop safe work procedures, provide training, and use visual aids like signage and floor markings.

- Personal Protective Equipment (PPE) – High-visibility clothing and safety footwear are essential but represent the least reliable form of protection.

6. Traffic Management Plans

Effective traffic management plans are crucial for separating forklifts from pedestrians. Plans should-

- Identify hazards and establish exclusion zones.

- Include clear diagrams showing forklift paths, pedestrian zones, and safety features.

- Be reviewed and updated after incidents, workplace changes, or at the request of HSRs.

Drivers’ safety zones with physical barriers should be established for loading and unloading areas. Forklift speed limits must be set and enforced, with a recommendation of 5–7 km/h in areas with pedestrians.

7. Safety Enhancements and Forklift Attachments

The guide emphasizes retrofitting forklifts with safety features, such as-

- Sequential Interlocking Seatbelts – Prevent forklift operation unless the operator is seated and buckled.

- Pedestrian Detection Systems – Automatically halt or slow forklifts to prevent collisions.

- Visibility Aids – Cameras and mirrors to enhance operator awareness.

- Dynamic Stability Control – To reduce tipping risks.

Attachments, such as jibs and work platforms, change the forklift’s stability and must be used in accordance with manufacturer guidelines. Each attachment must be inspected, securely fitted, and listed on the forklift’s capacity plate.

WorkSafe Victoria’s new Forklift Safety Guide.

8. Work Practices

The guide provides detailed instructions for safe forklift operation-

- Loading and Unloading – Use fixed barriers on docks and avoid raising forklifts unnecessarily.

- Restricted Operations – Prohibit pushing, pulling, or towing loads beyond the forklift’s capacity.

- Special Environments – Establish designated zones for refueling or battery charging, equipped with emergency tools like spill kits and eyewash stations.

Proper barriers on mezzanine floors and adherence to Australian Standards for load handling are highlighted.

9. Maintenance and Inspection

Regular inspection and maintenance are mandatory to ensure forklifts operate safely-

- Pre-operation checks must be conducted daily or at the start of each shift.

- Maintenance records should document inspections, repairs, and any identified defects.

- Forklifts with unresolved defects must be locked out of service until repaired by a competent technician.

Conclusions and Recommendations

The guide stresses a comprehensive and proactive approach to forklift safety. Employers and operators must-

- Understand Legal Obligations – Adhere to the OHS Act and Regulations.

- Promote Risk Awareness – Identify hazards, assess risks, and implement suitable controls.

- Ensure Competency – Provide comprehensive training and enforce strict supervision.

- Maintain Equipment – Conduct routine inspections and integrate advanced safety features where practicable.

- Foster a Culture of Safety – Encourage consultation and continuous improvement in workplace practices.

Summary

The guidance also encourages employers to consider retrofitting relatively low-cost safety technology such as sequential seatbelt interlocks, which prevents the forklift being started without a seatbelt in place, and proximity devices that detect pedestrians and automatically power mobile plant down to low speed.

By following such guidance, workplaces can significantly reduce the risks associated with forklift operations, ensuring a safer environment for all.

Resources:

Safe Work Australia: Safe Work Australia – COP Managing Risks Plant

NSW: Safework NSW – Fork Hazards Resources

Queensland: Worksafe – Workplace Forklifts

Follow FTMA Australia for Industry News and Updates

Our Principal Partners