This article was written and provided by Andy McNaught, Technical Manager of EWPAA on 7 September 2020.

LVL use in Australia is growing for all classes of building in Australia, but particularly in residential construction. Supply comes from domestic and imported manufacturing sources, both large and small. So how does the user of LVL have confidence in the product specified? Unfortunately, this is not as easy as looking at the brand or even the certification marks on a product.

To understand the issue needs some background in the “approval” process for buildings in Australia.

All buildings must comply with the requirements of the National Construction Code (NCC). Compliance with the NCC is met by meeting the stated performance requirements of that document. This can be achieved by following deemed-to-satisfy solutions, a performance solution, or a combination of both. NCC BCA Vol 2 Part 3.4.3 lists the acceptable construction manuals and procedures, that if complied with, meets the relevant performance requirement. Almost all residential construction and most commercial construction relies on the NCC deemed-to-satisfy solution and that means the design procedures and requirements of AS1720 -Timber Design Code must be followed. AS1720 requires LVL to conform to all requirements of the LVL product standard, AS/NZS4357 Structural LVL.

Simply put, if the LVL you are using does not comply with AS/NZS4357, it does not meet the requirements of the NCC.

It is become apparent that some LVL available in the Australian market does not meet AS/NZS4357, even though it is branded as such..

This article will provide users and specifiers with the information they need to make informed decisions about building with LVL so that they comply with the National Construction Code (NCC).

The key requirements of the AS/NZS4357 are:

Required – Publication of characteristic (structural) properties

There is no such thing as a standard LVL grade in Australia. Manufacturers must determine all properties of their LVL and make these available to users. The options for making these available to users are:

- Publishing all the characteristic values (so that users can use these properties to design using AS1720)

- Branding with an F-grade classification (so that users can use the characteristic properties published in AS1720 to design or use AS1684 span tables to determine section sizes)

- Publishing span tables for each application.

Unless there is clear branding restricting the use of the LVL to certain applications (see branding section below), ALL characteristic values must be declared and published, or span tables published based on ALL of the characteristic properties. This means stiffness, bending strength, tension strength, shear strength, and compression strength for flat, edge and axial orientations, as well as joint strength for nails, bolts and screws.

Critical to truss fabricators is that nail plate tooth capacities need to be determined so that the truss design software provided by your nail plate supplier provides the correct truss design. Nail plate tooth capacities are proprietary and are derived from testing of nail plates on each LVL supplier’s product. So, if a truss fabricator uses LVL that has not been tested by the nail plate manufacturer, the fabricator are assuming the responsibility of assigning the correct nail plate for the truss design, not the nail plate supplier.

This all sounds technical but is important because you need to look beyond the branding on the product ensure that you can confidently use it. For example, at present, there is LVL in the Australian market branded E11 that does not have characteristic values or span tables published. You might assume it has an E value of 11GPa, but what about its bending, tension, shear, or compression strength? What about the joint group details? What nail plate tooth capacity does it have? You cannot design structures of any sort without all the characteristic properties and therefore what you might build or fabricate with this product does NOT COMPLY WITH THE NCC. A certifier could (and should) refuse to certify the structure. You would also be responsible for any truss failure designed with software from the nail plate supplier if you substituted LVL that has not had tooth capacities tested by the nail plate supplier.

Required – Branding:

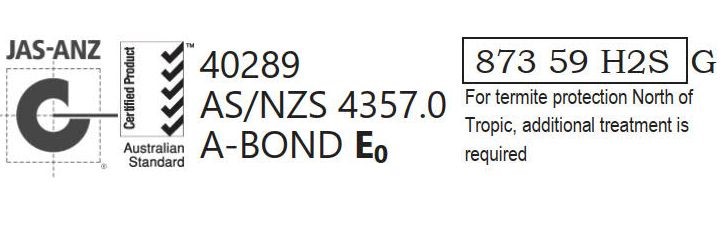

Branding must include reference to AS/NZS4357, the manufacturers name or registered mark, the bond type i.e. A-BOND, the formaldehyde emission class e.g. E0. It must contain marking that, in conjunction with published literature, clearly identifies the structural properties that apply to the product, clearly stated limitations of end use and, if preservative treated, branding in accordance with the preservation standard, AS/NZS1604.4. A certification mark is optional. Here is an example of a compliant brand on untreated product:

Most of this is self-explanatory. Probably the only confusion relates to the requirement “marking that, in conjunction with published literature, clearly identifies the structural properties that apply to the product”. The manufacturer can use a proprietary product marking such as LVL 11 as in the example above to describe the product provided there are either characteristic properties or span tables available to the user so that the building can be designed in accordance with AS1720 requirements and principles.

Preservative treated LVL needs to have a manufacturers name or treater code (who does the treatment), a preservative code (what chemical is used) and the Hazard class (how much chemical is there to meet the hazard that exists). In the example below, 873 is the registered number of the treater, 59 is the code for the preservative chemical and H2S is the hazard class.

LVL is usually treated to the following hazard classes:

- H2S – For protection against termites south of the Tropic of Capricorn. Does not protect against decay, so is unsuitable for deck joists or weather exposed framing. Common for internal house framing products

- H2 – For protection against termites in all areas of Australia. Does not protect against decay. Common for internal house framing products in Northern Australia.

- H3 – for protection against decay and termites but with no ground contact. Common for deck joists and exposed beams subject to rain wetting.

Additional codes are also present to give information about the distribution of the treatment chemical in the LVL:

- V = all the veneers are treated individually – generally used for severe H3 hazards

- E = an envelope treatment pattern – generally used for less severe H3 hazards

- G = glueline treated – generally used for H2S applications

- G/F = glueline and face veneer treated – generally used for H2 applications

Required – Manufactured in accordance with AS/NZS4357:

This is just about impossible for users to assess. Things like formaldehyde emission, bond quality, bond durability, the continuous validation of structural properties and other manufacturing requirements cannot be visually assessed. This is why the brand is important. The brand is a legal claim made by the manufacturer that it conforms with all aspects of AS/NZS4357. If they are branding product with this standard number without conforming in all respects, then they are misrepresenting the product and exposing your business to the risk that a structure will not meet NCC requirements.

Required – An initial evaluation of structural properties and continuous validation of those properties:

There are strict requirements in the way in which structural properties must be determined and monitored to ensure conformance with AS/NZS4357. This provides the confidence to designers and users that the product will be fit for use.

Optional – Certification:

Just because there is a certification mark on the product, it does not always guarantee conformance with the product standard. Bogus certification marks and certification based on limited product testing and without on-going or independent product testing exist in the market. If LVL has a certification mark but no span or application tables or published characteristic values, you can be certain that the certification mark is misapplied at best and could be fraudulent.

It is recommended that you look for products that certified to a Type 5 certification scheme, accredited to ISO 17065. Type 5 certification involves in mill process control and testing, third party audit of the manufacturing against product standards, on-going third-party testing of product and marketplace surveillance of product.

Indicators that LVL is likely to be conform with AS/NZS 4357 and therefore meets NCC requirements:

If ALL of the following are available, then it is a good indicator that you are buying or using a conforming product:

- Product is branded correctly

- The manufacturer’s website provides detailed product information

- The manufacturer provides characteristic design value for all properties or at least has technical people who can make these available to designers. This includes Stiffness, Bending, Tension, Compression, Shear Strengths and Joint Group details for all orientations that the product is used. Where these do not exist, proprietary span tables or design software is available.

- Technical assistance is available to assist with designing with the product.

- The nail plate supplier has tested the particular LVL product for tooth plate capacity and is prepared to state that their truss design software can be used for that brand of LVL.

If any of these are not present, it is a good indictor that the LVL does not comply and should not be used. Using non-compliant LVL, whether certified or not, means that you do not meet NCC requirements and a certifier can refuse to certify the structure. Frame and Truss companies who use non-conforming LVL risk replacement of the frame or trusses and legal action with state non-conforming building product legislation. They also assume responsibility for the selection of nail plate used in a design rather than the nail plate supplier.

This article was written and provided by Andy McNaught, Technical Manager of EWPAA on 7 September 2020.

Gold Sponsors