Written and provided by Andrew Kidd, Chair of the FTMA Frame and Truss National Safety Council

Many frame and truss manufacturers will regularly face the risks associated with delivering their finished products to site and finding that there are overhead electrical lines in the vicinity of the planned unloading area. There is an obligation for unloading to be undertaken safely and not to breach the relevant minimum “No Go Zone” or “Spotter Zone” working distances from overhead electrical lines. It is important to ensure safety or everybody who works in these high-risk zones. This safety requirement is a shared obligation placed on the manager or controller of the delivery site, usually the builder, the delivery driver – whether an employee or contractor and the supplier of the product – usually the frame and truss manufacturer.

Whilst different jurisdictions each have their own prescribed safety distances that must be maintained from overhead electrical lines (Victoria and South Australia are the same), there are some basic best practice principles that should be followed when undertaking work near energised overhead electrical lines with any type of plant, including Vehicle Loading Cranes (VLCs).

Safe Work Australia has issued an easy-to-follow guide aimed at preventing serious accidents and injuries or fatalities caused by cranes, VLCs and other mobile plant operating near overhead electric lines. The guidance outlines legal duties, practical safety controls, and procedures for all employers, contractors, and plant operators who work in high-risk zones near electrical infrastructure.

Working close to overhead powerlines poses a major threat to worker safety, with incidents often resulting in burns, electrocution or other fatal injuries. The guide focuses on ensuring these hazards are properly identified and managed through risk elimination and reduction strategies.

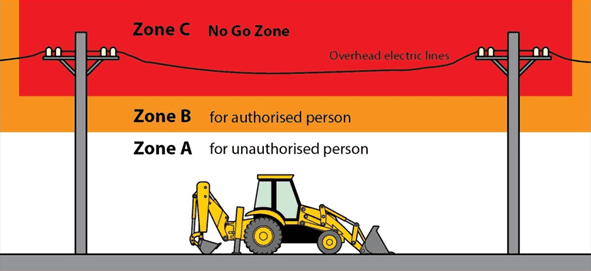

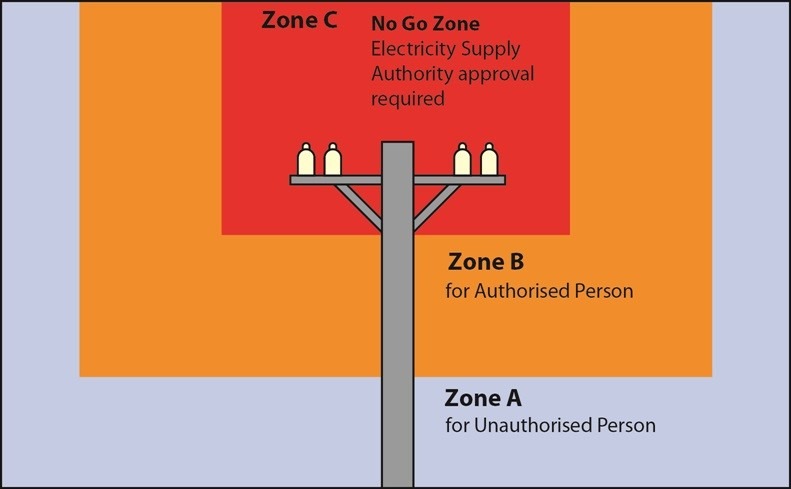

At the heart of the guide is a three-zone safety model, defining proximity-based risk levels for operations near powerlines:

- Zone C (No Go Zone)- The closest and most hazardous area around live electric lines. Entry is strictly prohibited unless written approval is obtained from the relevant Electricity Supply Authority and the lines are de-energised or isolated.

- Zone B- A buffer area where only authorised and trained personnel may operate cranes or plant equipment. Safety observers and other protective measures are mandatory.

- Zone A- The safest of the three zones, intended for unauthorised personnel with limited risk of contact.

The guide underscores the importance of planning and communication before any work begins. It recommends contacting electricity providers to discuss de-energising or relocating lines where practicable. If such actions aren’t possible, strict control measures must be applied based on the hierarchy of control approach.

These controls include-

- Substitution- Using alternative machinery or work methods that avoid entering hazardous zones.

- Isolation- Installing barriers made from non-conductive materials like plastic or wood to prevent inadvertent entry.

- Engineering Controls- Fitting cranes with limit switches, mechanical stops, or programmable zone limiting devices to prevent intrusion into danger areas.

- Administrative Controls- Using warning signs, visible markers (such as tiger tails on lines), site supervision, safe work procedures, and ensuring workers are trained and briefed.

- Personal Protective Equipment (PPE)- Recommending insulated gloves and mats for workers who may inadvertently come into contact with conductive parts.

A key requirement outlined in the guide is the development of a Safe Work Method Statement (SWMS). This document should detail the nature of the high-risk work, hazards involved, control measures in place, and the qualifications of those performing the work. The SWMS must be readily available on-site and understood by all relevant workers involved in the high-risk work.

The guide also sets clear expectations for safety observers / spotters, who must remain alert and maintain clear communication with crane or plant operators. Their role is to monitor movements near Zone B, warn of potential breaches, and stop work if required. Importantly, one observer must not monitor more than one piece of equipment at a time.

Additional precautions are outlined for workers in contact with cranes, loads, or plant equipment. The document stresses that operators and ground personnel should avoid simultaneously touching a crane and standing on an earthed surface, unless properly insulated. In some cases, remote controls, insulating mats, or gloves may be used to minimise risk.

Safe Work Australia further recommends affixing warning labels on cranes and plant equipment that clearly display approach distances, especially for unauthorised personnel.

The guide complements other resources such as codes of practice, industry-specific information sheets, and case studies that explore real-world incidents involving contact with powerlines.

Supporting resources:

Safe Work Australia: Guide Operating Mobile Plant near Overhead Electric Lines

NSW – Work near overhead power lines – Code of practice

QLD: Electrical Safety Code of Practice – working near overhead electric lines

SA: Working Safely Near Overhead Powerlines

VIC – Using powered mobile plant near overhead assets – guidebook

Follow FTMA Australia for Industry News and Updates

Our Principal Partners