Written and provided by Andrew Kidd, Chair of the FTMA Frame and Truss National Safety Council

Current Forklift Safety Features: Enhancing Workplace Safety and Efficiency

Forklifts are necessary, but there are risks

Forklifts are indispensable in the truss and frame manufacturing industry, they play a key part in moving pallets, packs of timber, finished goods, handling heavy loads and ensuring operational efficiency. Their ability to move heavy loads quickly and efficiently makes them indispensable. However, their operation is not without risk. Forklifts are usually large powerful machines that, without proper safety measures, can cause significant injury, property damage, or even fatalities.

Common forklift-related hazards include –

-

- Collisions with Pedestrians

- Collisions with Other Mobile Plant

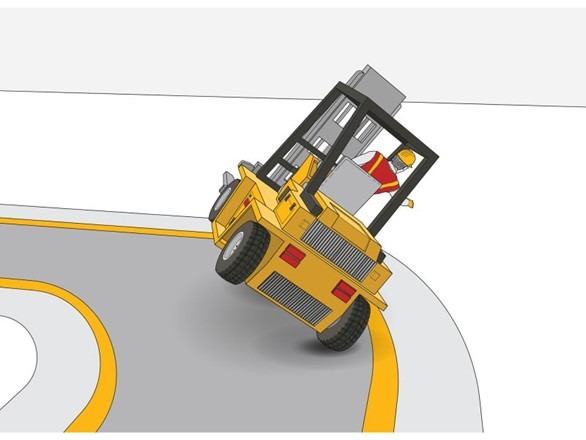

- Instability and Overturning

- Operator Ejection

- Falling Objects

Technology advancements in recent years have enabled the development of modern forklift safety features that are designed to mitigate many of these risks, enhancing workplace safety and operational efficiency.

Following on from FTMA Safety Matters #2 Forklift Safety in the Workplace (Nov 2024) this article explores the growing necessity of forklift safety features and the benefits brought by the newly available safety features that can be fitted to forklifts and load handling equipment.

The Rising Need for Enhanced Forklift Safety

The importance of forklift safety should be obvious and cannot be overstated. According to the Safe Work Australia 2023 statistics, forklift-related incidents are a leading cause of workplace injuries and fatalities. The hazards associated with forklifts often stem from operator error, lack of visibility, overloading, or interaction between forklifts and pedestrians.

Safe Work Australia reports that between 2015 and 2019, there were 62 fatalities and over 6,000 serious injury claims involving forklifts. In Victoria alone, more than one worker every week is seriously injured after being struck by forklifts or falling forklift loads. Fines and undertakings totalling more than $2.4 million were imposed or accepted by the courts for 16 WorkSafe prosecutions involving forklifts.

For business owners, such incidents result in a range of consequences beyond the obvious safety risks, including workplace disruptions, legal liabilities, compensation claims, and increased insurance premiums. Beyond compliance with Work Health and Safety (WHS) laws, ensuring forklift safety is an essential measure to safeguard employees and maintain uninterrupted business operations.

Modern forklift safety features address these concerns by leveraging advanced technology to minimise risks, enhance visibility, and provide safer forklift operations in the workplace.

Modern forklift safety features

Below is an explanation of the top 10 most common key safety features in modern forklifts that are readily available and redefining the safety standards you should look for in your forklifts and other load handling equipment.

1. Seat Belts

Basic yet essential, seat belts are mandated and continue to play a pivotal role in operator protection. Seat belts keep operators securely in place during a collision or tip-over. They must be fitted, operators must wear them, and employers must enforce the correct use of them. As a bare minimum you should consider fitting your forklifts with a bright coloured safe-belt or ‘Springbelt’ that is difficult to sit on, gets in the way when not worn and can be seen from a distance that it is being worn correctly.

Image 1 and 2 – Safe-Belt

Seatbelt non-compliance remains a significant safety concern which can be minimised by the current ‘smart seatbelt’ technology. Seatbelt sensors and sequential seatbelt interlock monitors ensure that operators fasten their seatbelts before operating a forklift. These systems either alert the operator or prevent the forklift from starting until the seatbelt is secured. This feature helps enforce seatbelt usage policies, ensuring a baseline safety measure is always followed.

Image 3 – RCT – Sequential Seatbelt Interlock

2. Operator Presence Systems

The next step up from a ‘smart seatbelt’ is the Operator Presence System OPS. OPS ensures that the forklift cannot be operated unless the operator is properly seated. If the operator leaves the seat, the system automatically disables the lifting and movement functions. This prevents unintended movement or use of the forklift, significantly reducing the likelihood of runaways or operation by unauthorised personnel.

3. Load Weight Indicators

Improper load handling, such as exceeding weight limits or unbalanced stacking, can compromise forklift stability. Modern forklifts are equipped with load weight indicators that display the weight of the load being lifted. These devices measure the weight of a load and its distribution, warning operators when the load exceeds safe operating limits or is unevenly balanced and helping operators stay within safe operational limits. In some cases, they will even prevent the lifting of loads that exceed safe limits.

Image 4 – CombiLift Weight gauge and SafeLift feature

By adhering to safe lifting capacities, businesses can avoid equipment damage, reduce the risk of tipping, and help protect operators and bystanders from injury.

4. Stability Control Systems

Forklift tip-overs are among the most common and deadly types of accidents. To prevent this, many modern forklifts now include advanced stability control systems. These systems use sensors to monitor the forklift’s speed, load weight, mast position, and tilt angle. If the system detects conditions that could lead to a tip-over, it automatically adjusts performance by limiting speed or lift height and alerting the operator. These systems significantly reduce the risk of rollovers, especially when handling heavy or uneven loads. This not only protects operators from injury but also prevents damage to goods and equipment.

Image 5 – WorkSafe Victoria – Forklift Instability

5. Automatic Speed Reduction

In addition to load sensors, forklifts can also utilise speed sensing and reduction systems to ensure safe and controlled operation. These prevent excessive speed in critical areas like reduced visibility corners, turns, ramps, or pedestrian zones. These systems use sensors to monitor the speed of the forklift and automatically reduce it when necessary, such as when turning corners or operating on uneven surfaces. They can also reduce a forklifts speed based on location, turning angle, or proximity to hazards. They can be based on zones within a workplace, on GPS locations or based on the load being carried or the height or angle of the mast. By controlling speed in real time, these systems reduce the likelihood of accidents caused by excessive momentum, such as tipping over or striking personnel or infrastructure.

6. Cameras, Pedestrian Detection and Collision Avoidance Systems

Blind spots and limited visibility have long been concerns in forklift operation. Forklift cameras improve operators’ visibility, particularly in areas where obstacles or blind spots make it difficult to see. These cameras provide a clear view of the surrounding environment, which may include rear, front, or side perspectives, displayed on an in-cab monitor in real time.

Rearview cameras and proximity sensors provide operators with a better view of their surroundings. These systems alert drivers to obstacles, personnel, or other vehicles in their path, especially when reversing or manoeuvring in tight spaces.

Additionally, forklifts can now be equipped with AI-driven pedestrian detection and automatic collision avoidance systems. These systems are completely autonomous and can recognize human movement nearby and either alert the operator or stop the forklift automatically to prevent an accident.

Image 6 – RCT – Forklift AI Pedestrian Detection

These readily available technologies offer a last line of defence in dynamic work environments, particularly where pedestrian traffic is high or the work area is congested. They provide critical reaction time and help prevent severe injuries.

7. Safe to Approach Lighting Systems

The ‘Safe to Approach’ light system is a colour change light bar to replace the standard forklift safety beacon (flashing orange light). It is a feature that can be fitted to equipment such as forklifts and is designed to provide clear and immediate feedback to individuals in proximity to the forklift if it is safe to approach. The system is invaluable when staff must approach forklifts to converse with the operator or give them some paperwork. When the forklift is in motion or the park brake is not applied, i.e. it is unsafe to approach, the forklift displays the usual amber flashing light, signalling pedestrians must not approach. Once the equipment is stopped, park brake applied and determined to be safe for approach, the usual flashing light changes to green, visually confirming to the pedestrian that the forklift is safe to approach. This straightforward, color-coded signalling system minimises uncertainty, promotes situational awareness, and ensures compliance with established safety protocols, and assists in preventing accidents in dynamic work environments.

8. Lighting and Warning Systems

Forklifts equipped with LED headlights, brake lights, red or blue safety spotlights or line projectors, and audible alarms enhance visibility and alert pedestrians and other operators to the presence of the forklift. These systems are particularly important in low-light or noisy environments, such as production environments and outdoor yards. Enhanced visibility and audible alerts significantly lower the chances of collisions and increase awareness of forklift activity in shared spaces.

9. Telematics and Fleet Management Systems

Telematics systems collect and transmit real-time data on forklift usage, maintenance needs, operator behaviour, and safety compliance. They can include the completion of onboard electronic daily equipment checks and they can be linked to High Risk Work Licence expiry dates to ensure only current licenced operators can access forklifts. Mangers and safety staff can use this data to monitor operations, identify risky behaviour, schedule preventive maintenance, and ensure adherence to safety protocols.

10. Ergonomic Design and Operator Comfort

Modern forklifts are increasingly designed with ergonomics in mind. Adjustable seats, intuitive controls, reduced noise and vibration levels, and improved cabin visibility all contribute to operator comfort and reduced fatigue. Comfortable operators are more alert and less prone to errors caused by strain or fatigue. Ergonomic designs contribute to long-term health, reduce repetitive strain injuries, and support sustained productivity.

The Benefits

The integration of these common safety features into forklift operation offers several compelling benefits for business owners and their teams.

- Reduced Accidents and Injuries

By leveraging technologies such as pedestrian detection and forklift cameras, organisations can significantly reduce incidents of crashes, collisions, and tipping. This proactive approach to safety reduces the risk of workplace injuries, creating a safer environment for all employees. - Cost Savings

Workplace injuries and accidents often lead to direct costs such as compensation payments, legal fees, and insurance premium increases. Indirect costs, such as lost productivity and employee morale, also add up quickly. Implementing modern safety features acts as a cost-prevention strategy, ultimately saving businesses money in the long run. - Improved Productivity

Safety features such as telematics and operator assistance systems allow for better operator control, reducing the margin for error and downtime due to equipment misuse or malfunction. Improved confidence among operators leads to enhanced efficiency in handling materials. Additionally, fewer accidents mean fewer interruptions to workflow, contributing to overall productivity gains. - Enhanced Compliance

Compliance with WHS regulations and industry safety standards is non-negotiable for businesses operating forklifts. Features such as seatbelt sensors and telematics ensure that operators are adhering to safety protocols. Monitored compliance through these technologies reduces the risk of fines or legal complications associated with non-compliance.

Conclusion

Modern forklift safety features create safer, more efficient, and compliant workplaces. From pedestrian detection systems and forklift cameras to telematics and operator presence technology, these features contribute significantly to the reduction of workplace accidents, operational disruptions, and associated costs.

For businesses, investing in forklifts with modern safety features is not just about compliance with WHS expectations, it is a strategic decision that enhances operational reliability, reduces premium costs, liability, and demonstrates an commitment to employee well-being.

Follow FTMA Australia for Industry News and Updates

Our Principal Partners