Written and provided by Andrew Kidd, Chair of the FTMA Frame and Truss National Safety Council

Noise is a Common Hazard

In early September the FTMA had a few members make contact asking about the rules surrounding noise exposure and the requirements for noise level testing and hearing protection. Those enquiries prompted the topic for this, my first “Safety Matters” newsletter.

If you were like me and grew up going to see live music in pubs during the ‘70’s, then you’ve likely experienced lying in bed at night with ringing ears after listening to a full set of AC/DC at the Station Hotel. I was an AC/DC fan because I grew up in the housing commission flats in South Yarra with their bass guitarist, Mark Evans, we lived on the same floor. Whichever loud concert you went to, you probably recovered OK by the next morning and didn’t need to worry, but the ear ringing and temporary loss of hearing are signs that you are doing yourself harm.

We know that different people have different hearing levels. People can be born with reduced hearing or lose their hearing through injury or disease. It is also common to experience some reduction in hearing as we get older. Exposure to loud noise at work, through recreational pursuits, or from environmental factors can also result in hearing loss.

Like many industries, noise is a common hazard in the Frame and Truss manufacturing industry, and it is well known that exposure to high noise levels can be distracting and even harmful to the point of causing permanent injury if exposure continues over time.

When exposed to loud noise continually over a period of time, the nerve cells in the inner ear may eventually die and not respond to sound. This condition is called noise induced hearing loss and usually occurs gradually over many years like hearing loss due to ageing.

Andrew and Kersten at a recent safety meeting

All jurisdictions in Australia have set the same maximum noise exposure limits for workers. The common requirement is, if employees in your workplace are exposed to noise that exceeds the exposure standard of 85 dB(A) averaged over an eight-hour period or a peak noise level of 140 dB(C) then your workplace is too noisy. (Note: dB is the abbreviation for the decibel – the unit used for sound pressure levels on a logarithmic scale).

You can reasonably presume your workplace has noise in excess of the maximum exposure standard, if any one of the following occurs:

-

-

- employees have to raise their voice to communicate at a distance of 1 metre;

- employees have a temporary reduction in hearing or ringing in the ears after leaving work for the day; or

- employees use hearing protectors, ear plugs or muffs, during their work.

-

If you are not sure whether there is a noise problem, some spot noise measurements may help. There are numerous noise level Apps that are available for smartphones, all of which can provide an indicator if there is a concerning level of noise in your workplace.

The examples below provides some general advice on typical noise levels for common tools and equipment used within the frame and truss manufacturing environment. Actual levels for the tools and equipment in your workplace, however, may vary significantly from these figures.

-

-

- 120 dB (A) – Hand hammering nail plates to timber components (on a table press)

- 115 dB (A) – Pneumatic fasteners (Stapler Duofast SW1748)

- 112 dB (A) – Framing console (4 x nail guns)

- 110 dB (A) – Pneumatic fasteners (handheld nail gun)

- 107 dB (A) – Drop saw Makita LS1040

- 98 dB (A) – Drop saw, Hitachi C10FSH

- 92 dB (A) – Swing saw – open blade cross cut

- 90 dB (A) – Clicker Press ATOM

- 88 dB (A) – Gantry / Roller press

- 85 dB (A) – Forklift operation (in operator’s seat)

- 78 – 85 dB (A) – Fully enclosed linear feed saws

- 75 dB (A) – Floor truss jig table

-

If there is uncertainty as to whether the employees are exposed to noise that exceeds the noise exposure standard, then you should arrange conduct a noise assessment to determine an employee’s exposure to noise. Uncertainty can arise when noise in the work environment is variable, there are multiple sources of noise, and the duration of an employee’s exposure varies.

Usually, a noise assessment will be made using a combination of noise spot measuring devices, measuring the noise emitted by particular tools or equipment, and a dosimeter, a devise worn by employees at their ear position with measurements taken over a period of time that is representative of the process, activity or work pattern being assessed.

Noise assessments must be redone if there is any substantive changes to the noise levels in the workplace, such as a change of equipment or layout, or after five years. The assessment would no longer apply if there have been changes in the sources of the noise such as new equipment introduced or changes in how the job was done such as different time of day or location, or changes in the length of time a machine is on or being used. In this case, the assessment must be revised.

If it is confirmed that noise in the work environment is at levels above the exposure standard, then some key things should be implemented as a minimum:

- Implement appropriate risk controls – Consult with your HSR and staff to eliminate or reduce the exposure to noise according to the hierarchy of risk controls.

- Provide hearing protection to workers who are exposed to hazardous noise. The level of protection should match the hazard level of the noise. Employees must also be trained in the use, maintenance and fitment of their hearing protection.

- Install appropriate signs and labels in the areas, and on the machines, where employees are required to wear hearing protection.

- Arrange for audiometric testing for all employees working in areas that are exposed to hazardous noise levels. Testing must be provided within three months of an employee starting work and at least every two years thereafter.

- Employers must retain any audiometric test results and audiological examination reports as a confidential record for as long as the affected employee is employed by the employer. Copies of reports must also be given to the employees to whom they relate.

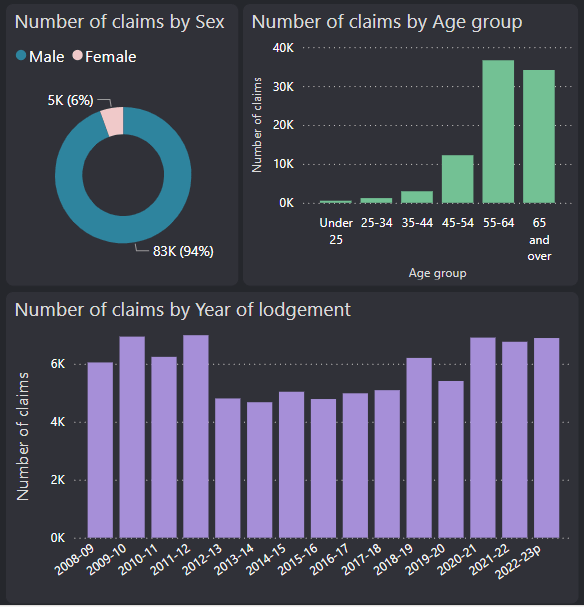

Workers’ compensation data shows that since 2018 there have been over 6,000 hearing related claims per year with over 95% of claims being made by males over the age of 55 years of age.

The below graph from Safe Work Australia highlights the extent of the problem.

Noise exposure in our industry is a common hazard that can result in damage to hearing and resultant workers compensation claims which will drive up our industry’s insurance premiums.

It is worth noting that if noise can be controlled without relying on hearing protectors, then hearing tests don’t have to be provided. Hearing tests must be provided where hearing protectors are required to make sure that employees’ exposure does not exceed the noise standard.

Our Principal Partners