This piece was written and provided by FTMA Supporting Partner, Hundegger Australasia.

Nestled in Queensland’s Redlands region, RBRT (Redland Bay Roof Truss) is a second-generation, family-owned timber fabrication business that’s doing more than just building frames – it’s building a legacy.

Established in 1988, RBRT has grown from humble beginnings into a forward-thinking manufacturing business that supplies timber framing components to a wide range of residential and commercial projects across South East Queensland and beyond. Today, Drew Parker leads the business as CEO, Director, and 50% shareholder, bringing both a deep respect for tradition and a clear vision for the future.

For Drew, timber is more than just a material – it’s a sustainable building solution.

“It’s environmentally friendly to build with timber because it’s sustainable and renewable. We’re planting trees as a way of building homes” he says.

Despite its local name, RBRT’s reach extends far beyond the Redlands. “We’ve always been based here,” Drew says, “but to grow, we’ve had to expand our geographical footprint.”

That expansion has seen RBRT’s deliveries stretch as far north as Rockhampton and Gladstone, down the coast to Coffs Harbour, and into Sydney for key clients. Yet despite this growth, the company remains deeply committed to servicing its home region first.

Like many in the industry, RBRT has faced challenges with labour shortages, a problem that’s been offset through strategic investment in automation.

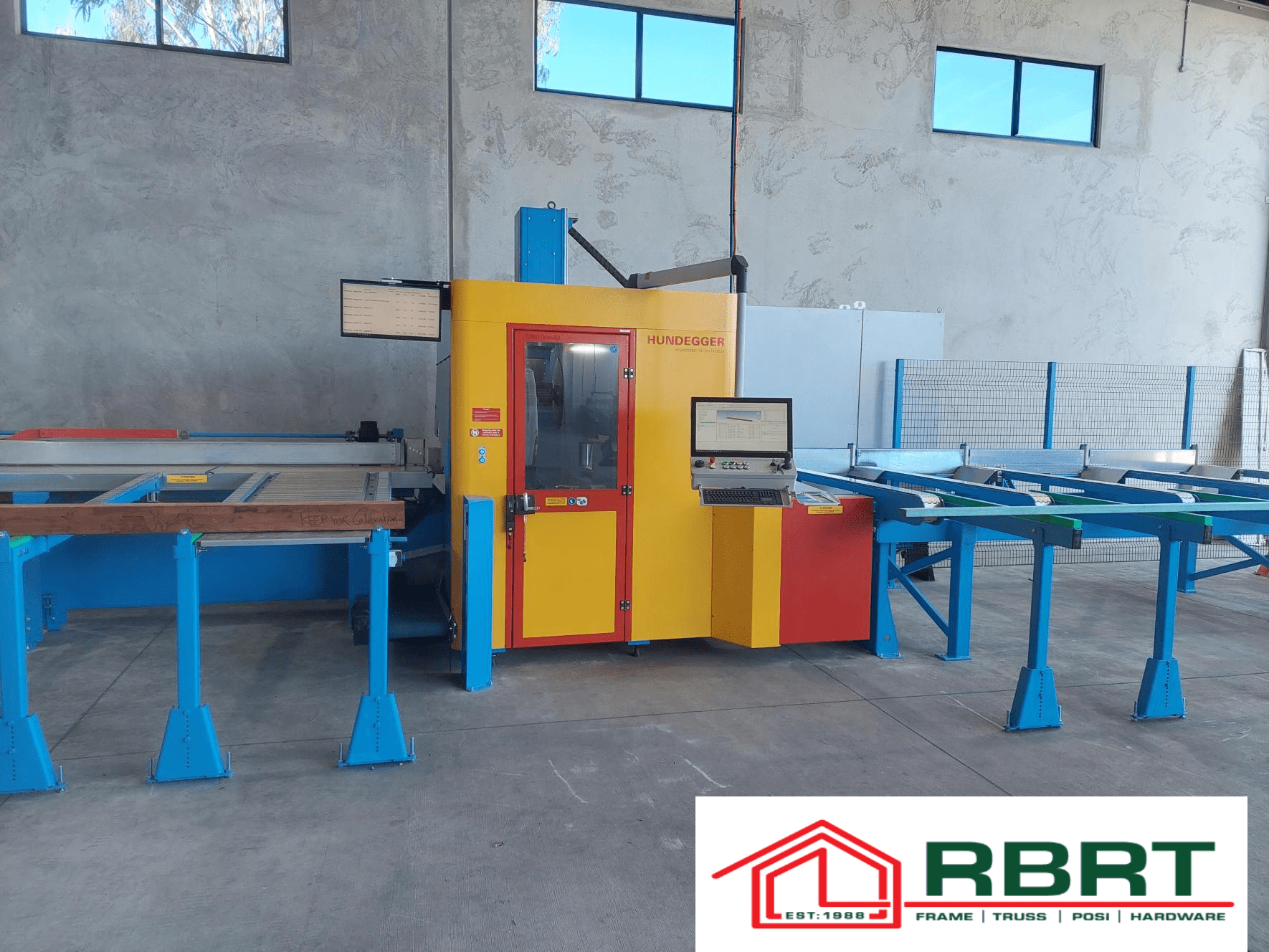

Enter Hundegger. RBRT’s first SC2 saw was one of the earliest of its kind in Australia. But recently, they took a big leap forward with the addition of the Hundegger Turbo Drive II.

Capable of handling high-speed, multi-angle cuts with pinpoint precision, the Turbo Drive II boasts advanced software and automation, a compact footprint with maximum output, multi-piece cutting and marking for efficiency, and seamless integration with design and CAD systems.

This smart investment has allowed RBRT to increase their wall frame cutting output by up to 40%, producing up to 1,400 components per shift, while reducing floor space and manual handling.

The new saw has had a transformative impact on production. “It’s faster, more efficient, takes up less floor space, and runs new software,” Drew explains. “It’s making a real difference in our production line – especially in wall frame manufacturing.”

At RBRT, innovation and heritage sit side by side. While the business continues to embrace new technologies and expand into new markets, it does so with the steady hand of a family business built on strong values.

“Automation gives you accuracy, efficiency, and reliability, especially when labour is tough to find. But it’s also about delivering better outcomes for our customers,” Drew says.

With sustainability in focus, a skilled team on the ground, and cutting-edge tech at their fingertips, the future looks bright for RBRT.

Learn more about the RBRT operations by watching Hundegger’s latest ‘Customer Insights’ episode on YouTube

Follow FTMA Australia for Industry News and Updates

Our Principal Partners