Circular Economy And the Timber Circulatory Project

This piece was written by FTMA’s Kat Welsh.

The principles of circular economy, in so many ways, are incredibly simplistic. But yet, applying them seems incredibly complicated – when much of society has been driven by concepts of consumerism, capitalism, and casting away. With the Industrial Revolution, came enormous changes to human existence, including waste. In 1900, King C. Gillette came up with idea of disposable razor blades attached to a crafted steel handle. With the onset of the 20th century came plastics, nylons, Bakelite, disposable kitchen items, household appliances, cars, the list goes on – all sold as the solution to revolutionise our lives. But with it, began the problem of landfill, and mass emissions.

How many times have we heard our parents say, something like, “things aren’t made to last anymore”? The throw-away generations have snow-balled to the point where we chuck stuff in the bin without a second thought. While there were many benefits stemming from the Industrial Revolution – the technological advancements that came have created some of the best parts of our society today – it has come at a cost. With the increase of global populations, the raw materials that at first seemed like they would last forever, are depleting, and waste products are clogging our planet. This is what is known as a linear economy.

Possibly this mindset, comes from thousands of years’ worth of living in harmony with the planet, and the fact that we were part of a natural balance – what we discarded, if anything, was able to biodegrade and contribute to the growth of something else. Having to be conscious about polluting our planet with what we pump out is a relatively new and post-industrial concern. But with the United Nations setting the estimated world population (as of September 21st 2023) at 8.1 billion, we can’t keep flushing things down the linear economy toilet.

Photo Credit: Global Waste Index

Nature is a balanced existence, where things grow, die, decompose, and provide matter for the next cycle. But humans, have created a system where products are made, the process of which often contributes to the output of dangerous chemicals and gases, things break, end up in landfill, do not decompose, nor create matter for anything to grow on.

Photo Credit: Ellen Macarthur Foundation

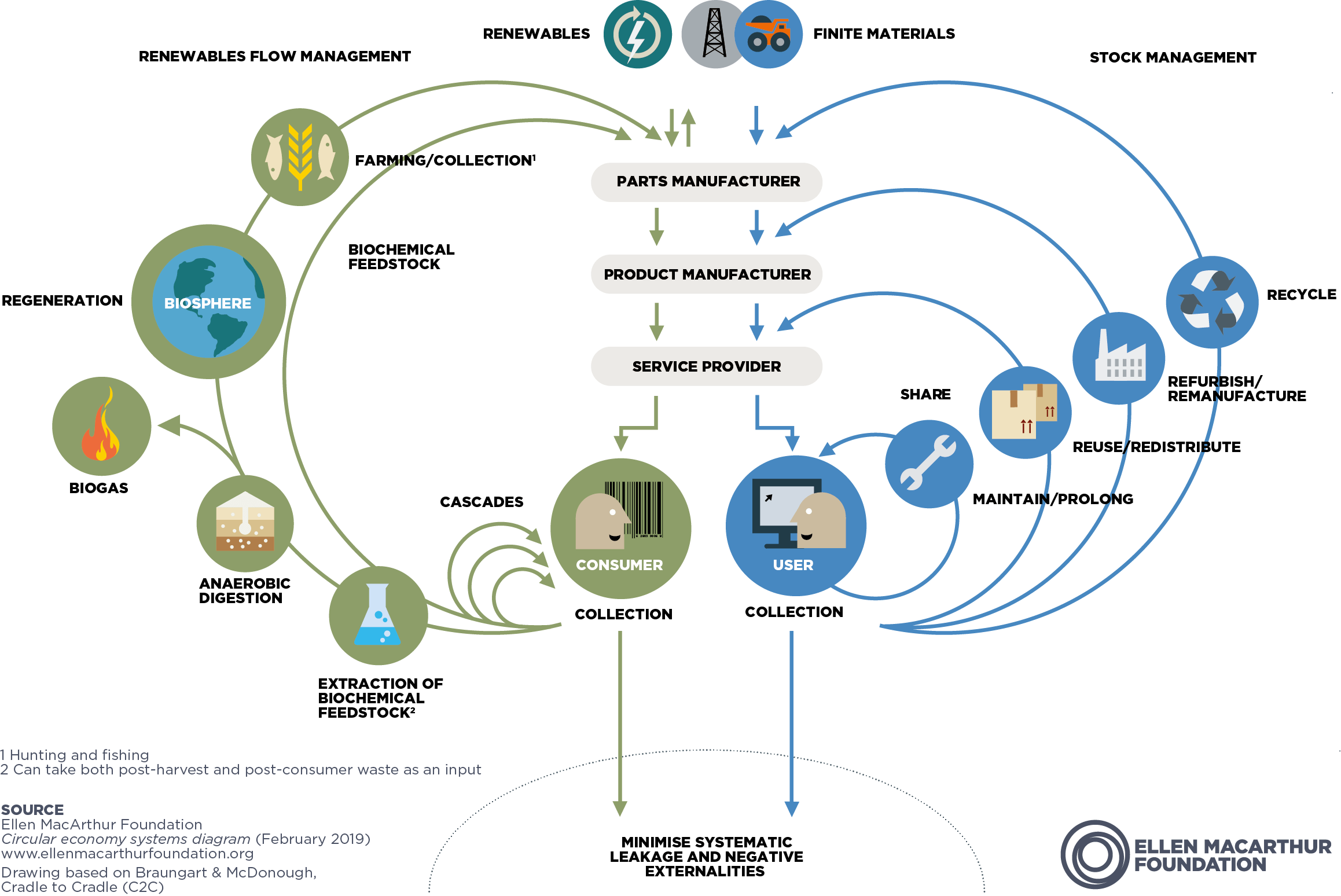

Circular economy is the process to achieve to reduce, reuse, recycle. “The circular economy is a system where materials never become waste and nature is regenerated. In a circular economy, products and materials are kept in circulation through processes like maintenance, reuse, refurbishment, remanufacture, recycling, and composting. The circular economy tackles climate change and other global challenges, like biodiversity loss, waste, and pollution, by decoupling economic activity from the consumption of finite resources.” Ellen Macarthur Foundation.

We’re facing a crucial time in our existence – the edge of the cliff with climate change. How we’re making things and what we’re doing with them at end-of-life is paramount.

If we look at the building industry, and specifically timber, there are some key considerations. Wood is renewable. It stores carbon. It is the best resource we have to assist in pulling CO2 out of the atmosphere, while we work on reducing what we’re emitting. Wood is also incredibly durable, and there are many examples of structures hundreds of years old, proving that wood can sustain long-term needs for the building industry. But, there are also some areas around using wood that need progression.

Treated wood, containing biocides or resins, can cause issues when it reaches the end of its initial intended purpose. Waste wood, and also end-of-life wood, from the building industry, needs to be considered. All of these materials are still storing valuable carbon.

With the Australian Government committing to “work with the private sector to design out waste and pollution, keep materials in use and foster markets to achieve a circular economy by 2030”, now is the time to do what we can to support the research that will help develop our industry.

The National Centre for Timber Durability and Design Life (University of the Sunshine Coast) is researching, and developing the future of wood, its durability, and its development as an engineered product. For the next 3 years, a major endeavour is the Timber Circulatory project – specifically focusing on the end-of-life possibilities for treated wood and wood waste, with the intention of developing opportunities to maintain and reuse as much carbon as possible – with emphasis on the wine industry, and frame and truss. FTMA has partnered with the centre to support this project, both for the environmental purpose, and to support the industry with better ways of dealing with waste.

As mentioned in July’s FTMA News, Chief Research Fellow, Dr. Penelope Mitchell, has already been conducting site visits in Queensland, researching quantities of waste, and current methods of disposal. Senior Research Fellow, Dr. Martin Strandgard has also been visiting sites based in Victoria. The team have begun testing treated posts from vineyards.

“We have an increasing world-wide timber shortage and a growing population which will lead to increased resource consumption, yet we continue to waste valuable resources. The circular economy is about keeping products and materials in circulation longer, however biomass flow remains very linear. We send an estimated 2.5 million tons of wood waste to landfill every year in Australia*. The major reason is that we cannot currently identify types of wood waste, do not understand the risks of cycling waste bask into the system, and regulations do not support possible solutions for circulating timber waste back into the system. The Timber Circularity project aims to characterise preservative treated timber (PTT) and engineered wood product (EWP) waste in order to understand potential future reuse and recycling challenges and opportunities which will support a circular economy.”

Timber Circulatory project.

Note: * Australia generated 2,369,680 tonnes of timber waste in 2016-17 (Maqsood et al (2019) Resource circular economy: Opportunities to reduce waste disposal across the supply chain – Timber, Sustainable Built Environment National Research Centre Australia).

By the end of the project what will be delivered will be concise details of how treated or engineered wood is being disposed of, the conditions of it, its ability to be reused or recycled, the most appropriate ways to do this, and looking at the feasibility of take back programs. There will also be a reuse / recycling program trialled with one type of product to measure issues, and approaches.

FTMA, and Carbon Warrior, fully support this project, and one of the key things that we’re passionate about is that offsite manufacturing, which in itself we all know, is significantly less wasteful than stick-built methods.

While the timber and engineered wood products sector is the significant way forward for construction leading into a carbon responsible future, we need to support what are some of the factors that will also make it a viable circulatory process.

We’re incredibly grateful to the FTMA members that have already shared knowledge and welcomed the collaboration with the Timber Circulatory project researchers, and we’re excited to keep sharing information with you all, as the project progresses. This project continues FTMA’s strategic commitment to Support, Invest, Grow as well as Carbon Warrior’s dedication to supporting change for the planet.

If you have any questions, please get in touch.

Our Principal Partners