Written and Provided by FTMA Supporting Partner, Hundegger Australasia

Earlier this year, the Hundegger Australasia team committed to spotlighting their customers in a bigger way online. Why? Because their customers are the driving force behind their success.

What better way to celebrate innovation in timber production and manufacturing than by showcasing some of the best in the Australian industry?

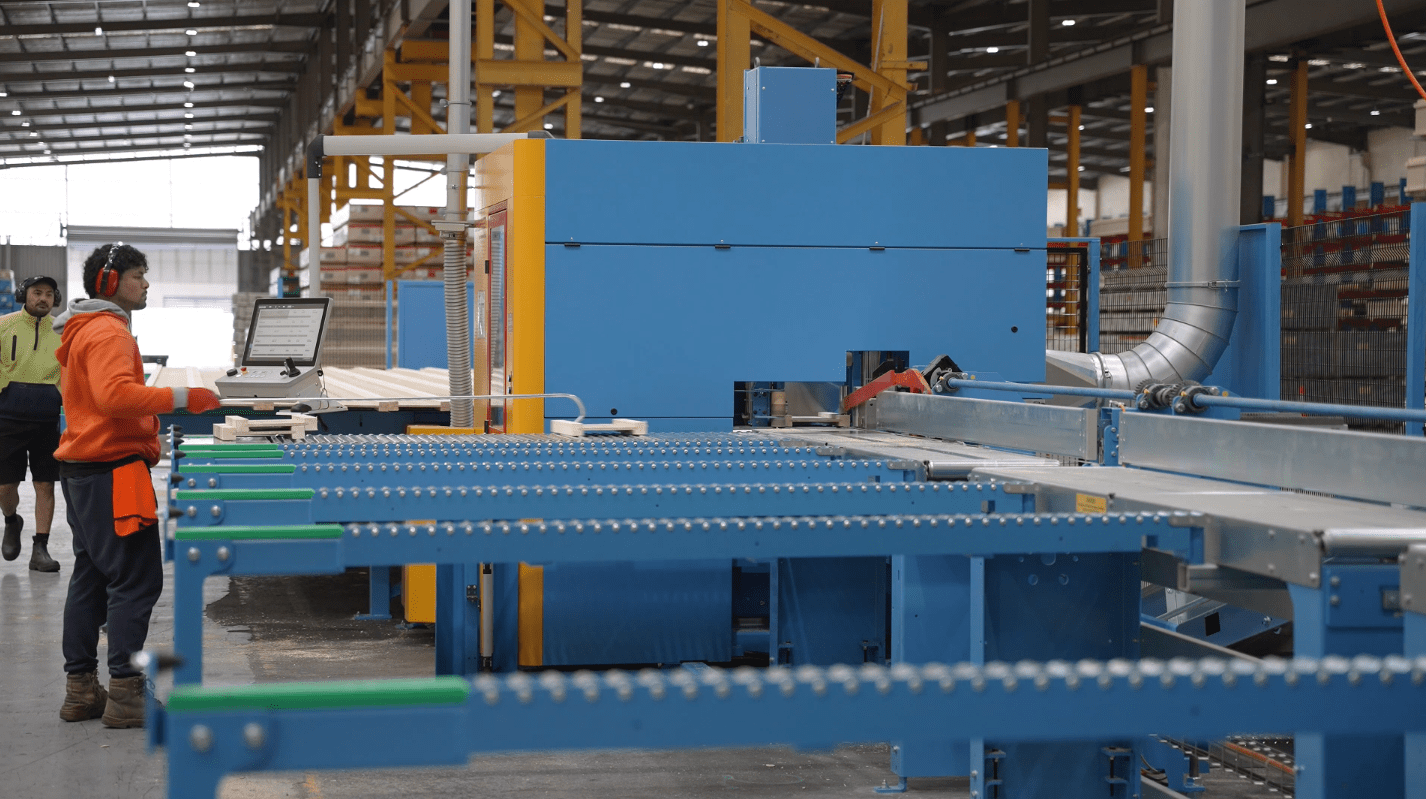

This vision became reality with ITI Australia starring in the first interview-style video, launched across YouTube and social media. On a cold and rainy day in July, the Hundegger team, videographers, and ITI representatives gathered at the Keysborough site to bring the concept to life.

The result? See for yourself: Watch the video here.

With Hundegger driving the project, it made sense to start with ITI, Australia’s largest timber distributor, who has a legacy of pioneering timber solutions since 1987. With eight facilities in Australia, three in New Zealand, a processing plant in Chile, and a sourcing office in Indonesia, ITI Australia consistently provides innovative solutions for builders. Their mission is simple yet ambitious: to “sell time” by streamlining construction processes with advanced timber products and systems.

A prime example of this vision is ITI’s adoption of Hundegger’s Turbo-Drive II, an advanced cutting machine tailored for engineered wood products. Hundegger, a global leader in timber processing technology, is renowned for its versatile and efficient machines that cater to industries ranging from roof truss manufacturing to cross-laminated timber processing. Their fully automated machines, such as the Turbo-Drive II, deliver unmatched precision and adaptability, making them indispensable for modern timber construction.

With more Hundegger’s set to be installed across the country, ITI Australia is not slowing down when it comes to production. Prioritising highly efficient machinery to aid their business growth, this cements their role as a leader in the timber industry.

The Turbo-Drive II, installed at ITI Australia’s Keysborough site, integrates seamlessly with ITI Australia’s CAD systems, allowing for precise modelling and streamlined production. This machine meets the growing demand for pre-fabricated timber solutions by offering cut-to-length services and customised markings. Additionally, it prioritises worker safety through advanced design features, a critical consideration in high-volume manufacturing environments.

Since its installation, the Turbo-Drive II has enabled ITI Australia to expand its product offerings, providing pre-fabricated timber solutions like I-joists that reduce on-site construction time and waste. ITI Australia aims to leverage this technology further by processing a broader range of engineered wood products, enhancing their ability to meet diverse customer needs.

ITI Australia are looking towards the future with this machine purchase, choosing to future proof it to allow additional automation to be added. This will allow ITI Australia to ramp up production in an automated style with their pick & feed / pick & place machine. Hundegger’s machinery is the epitome of automation, learn more below.

The partnership between ITI and Hundegger also reflects a shared commitment to sustainable and efficient timber processing. Hundegger’s machines are engineered to optimise resource use, reducing waste and promoting eco-friendly practices—a crucial factor as the construction industry faces mounting pressure to improve sustainability.

In an industry where time and precision are paramount, ITI and Hundegger exemplify how technology and innovation can drive progress, setting a new benchmark for timber manufacturing in Australia and beyond.

Follow FTMA Australia for Industry News and Updates

Our Principal Partners