This piece was written and provided by FTMA Strategic Partner, AKD.

In 2024, AKD commenced the installation of an advanced Lucidyne (now Microtec) GradeScan timber scanner, marking a significant milestone in the company’s commitment to continuous improvement. This installation is the final phase in AKD’s strategic transition of all its mills from Metriguard and visual grading to a fully automated grading system that leverages cutting-edge scanning technology.

AKD has historically relied on visual grading, a method that, while reliable, has struggled to consistently meet customer expectations and Australian Standards. This approach requires highly skilled timber graders to apply site-specific grading rules at high speeds, a process that inherently carries a risk of inconsistency.

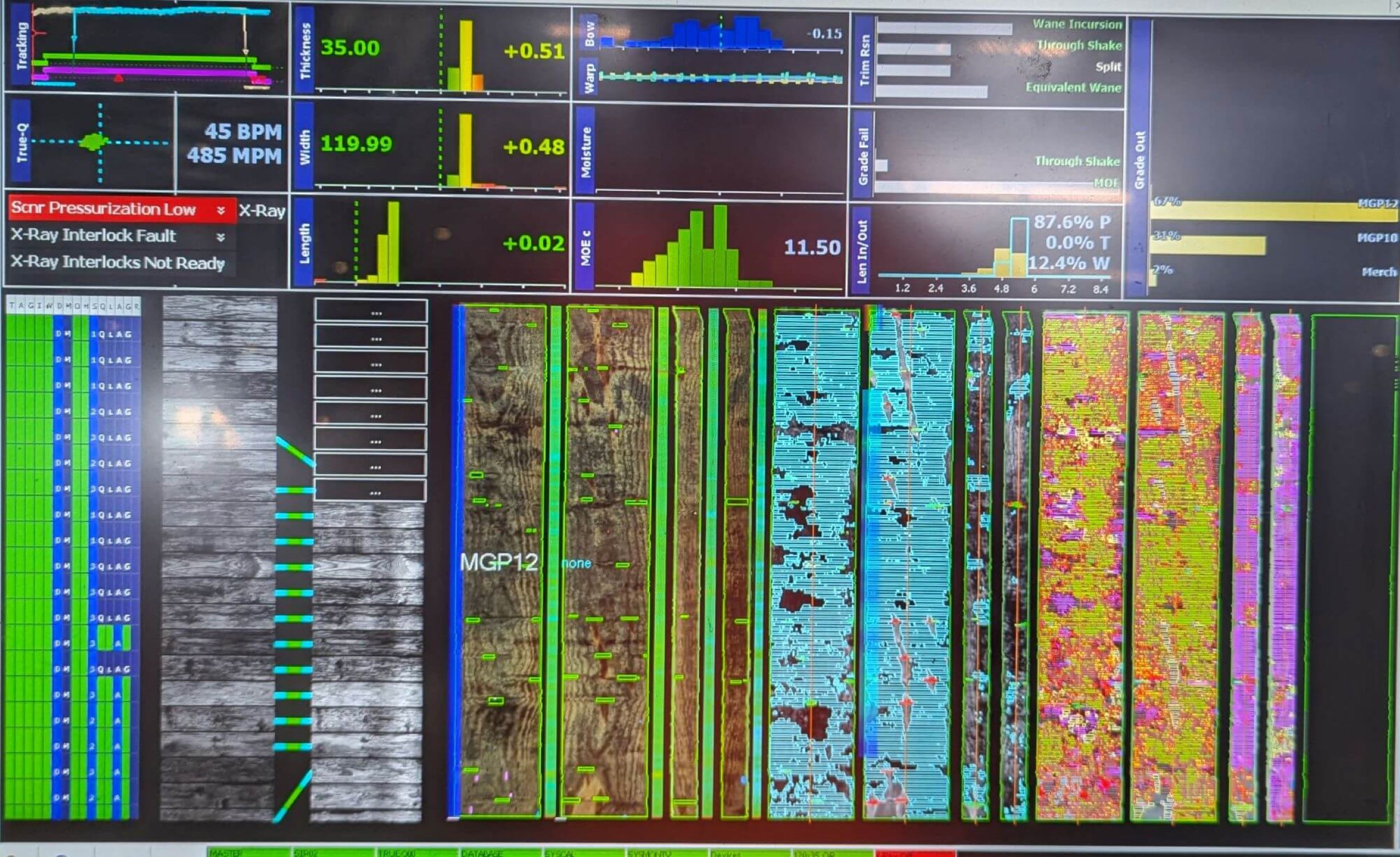

The primary advantage of automating Drymill using a timber scanner is the significant enhancement of product accuracy and consistency, which is reliably maintained over time. This advancement reduces reliance on the grader operator and ensures a more uniform classification of timber in accordance with industry standards, eliminating the variability that may arise from human assessment. The scanners utilise a range of technologies, including lasers, color cameras, x-ray imaging, and sophisticated algorithms to assess and measure defects such as knots, holes, wane, distortion, and splits.

“Installing the GradeScan and warp detection in the Caboolture Drymill marks the final step in equipping all AKD Drymills with the most advanced grading technology available. This upgrade significantly enhances accuracy, consistency, and uptime. While scanners demand a new skill set from our operators, they also eliminate the challenging task of visual grading at high speeds. As we continue to refine the algorithms and grade rules, we’ll keep pushing for the best results for both AKD and our customers, ensuring a consistent, high-quality product.” – Kim Harris, AKD National Technical Manager.

This technology enables timber to be sorted into precise grades. The commissioned machine, along with its quality control framework, significantly impacts both the quality and quantity of grade yields, reflecting AKD’s dedication to superior product standards. The scanner system collects extensive data, with each timber piece individually identified, improving traceability during inspections or research aimed at enhancing outputs. Moreover, AKD benefits from real-time data access, which enhances reporting capabilities and accelerates decision-making processes.

Since the installation of the GradeScan scanner, AKD has observed several significant improvements in daily operations. Efficiency has increased, as automation reduces the time required for manual assessments. AKD operators now enjoy a more streamlined workflow, with fewer bottlenecks that previously hindered manual grading processes. Additionally, the system’s ability to analyse historical data trends allows AKD to continuously refine grading criteria, ensuring the company remains at the forefront of industry standards and customer satisfaction.

Our Principal Partners