This piece was written and provided by FTMA Principal Partner, Pryda.

We’re incredibly proud of our diverse local Software, Sales, Engineering, and Builder Solutions teams and the work they’ve been doing to keep F&T design and manufacturing ahead of the curve. Pryda’s software is developed by our predominantly Melbourne-based team, exclusively for the ANZ market, enabling a steady flow of new features and fixes that capture what we’re hearing from fabricators, builders, and trades.

The Pryda Software Team at our office in Dandenong South, Victoria

Practical Experience and Builder Feedback to Accelerate Feature Development

There’s nothing better than getting the team out from behind their desks, into fabrication yards and out on site to experience the practicalities of building so we can accelerate the process of turning feedback into new features.

This year’s focus has been a structured deep dive into wall frames, gaining a comprehensive understanding of what is working well, and, more importantly, where there is scope for improvement.

Pryda team members Cici Cai and Rob Moore on one of their regular site visits

Conducting these sessions brings several benefits. Firstly, Pryda gains a clear understanding of areas that require improvement and identifies opportunities for new innovations. Secondly, our fabricator reaps the benefits through enhanced software, improved factory flow, manufacturing efficiency, and the ability to be the first to offer new innovations. Lastly, involving the builder right from the start allows for a streamlined, safer, and easier process on site, elevating their quality and efficiency levels and ultimately benefiting their customers.

Rob in his element, discussing the nuances of wall frame installation with a crew in Queensland

We recently had the privilege of collaborating with Big River Geelong MB Prefab, this year’s recipient of the National Timber & Hardware Award, along with one of their major customers, Hamlan Homes, renowned for their 40-year history in construction. Building these relationships that cover the entire process from the F&T quote to a completed structure on site, and being able to sit with our software developers to turn those insights into the next set of features, has accelerated our ability to give detailers the tools they need to produce designs that are easy to make and easy to build.

The feedback we’ve had is that these sessions feel meaningful and productive, with a sense from all three partners that the pieces of the puzzle are falling into place.

Understanding and Advancing the State of the Art

Our development team have also established strong ties with universities to advance timber framing. Our partnership with academic institutions involves participating in forums, workshops, and conferences conducted by universities, as well as initiating collaborative industry projects for students.

These joint initiatives serve as an exceptional platform for us to share expertise and highlight the vast potential for innovation and growth in timber framing. By exposing students to real-world challenges and encouraging their participation in problem-solving activities, we offer them valuable knowledge and experience while showcasing the endless possibilities and benefits of timber framing.

Our goal is to equip the young minds of today with practical insights and inspire their curiosity to innovate and contribute to a greener and more sustainable built environment. Together, we can pave the way for a brighter future where timber framing takes centre stage in residential construction practices.

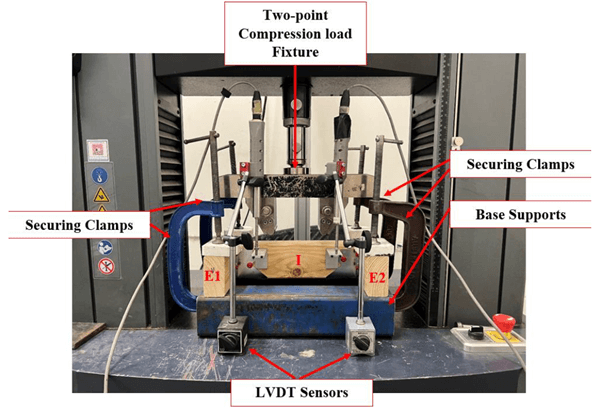

Pryda’s collaboration with Swinburne University undergraduate students provided hands-on experience in timber design and testing, while also contributing valuable insights to support further product development

Recent examples of these collaborative relationships include

- A testing-based project for two teams of undergraduates at Swinburne University to investigate the performance of various screw designs and configurations in common timber connections

- Two CAPSTONE projects (final year engineering projects) with RMIT students to investigate roof truss web optimisation and the potential for innovative designs of nailplated timber beams and flexural members

- Attendance by members of our software leadership team at RMIT Industry forums that serve as a platform to communicate and get the latest updates on the research

- Showcases of the Pryda software suite to interested academics and students, typically to support their CAPSTONE projects

- In-person support of RMIT and Deakin University’s final-year project presentations to continue these relationships as the students move into industry or further their academic careers

Moving Forward Together

Our Software Development Manager, Mina Kardani, recently discussed the future of timber framing with Dr Kazem Ghabraie and Dr Mahbube Subhani from Deakin University, and we’ll continue to use the podcast and our industry newsletters to share what we’re seeing, hearing, and working towards.

You can listen to Mina’s episode here or access the full library of episodes and subscribe using the QR code below.

Our Principal Partners