This piece was written and provided by the Timber Framing Collective.

As part of our goal to keep the structural timber category strong in the Australian market, the Timber Framing Collective (TFC) is focused on ensuring that, even with the pressure to grow supply longer term, there is no compromise on quality. Timber buyers in fabricators’ businesses should be checking their timber suppliers’ MGP certifications.

A reminder about who TFC is.

The Timber Framing Collective is responsible for the marketing of timber framing in Australia. Timber is in the DNA of Australian homes. It’s a living reminder of the connection we feel to the world around us and the duty we have to help preserve it for future generations. Timber framing is strong, versatile and, most importantly of all, endlessly renewable. The Timber Framing Collective exists to make sure those messages are heard loud and clear.

What we do

Currently, we are financially supported by Australian sawmills, importers, industry associations, peak industry bodies, building products suppliers and treatment suppliers.

Our mission is to promote, establish and consolidate Timber Framing – The Ultimate Renewable™ as the leading building materials brand in Australia for residential construction.

Structural Quality Assurance

As our local and global supply chains continue to adapt to the “new normal”, there is still the ongoing challenge to ensure “the right product for the right job”. In the Australian market, we continue to strive for timber supply reliability and quality assurance. With the growing demand for renewable building products, it is timely to reiterate how Structural Timber Framing supplied into the Australian construction market must comply with Australian Standards and is fit for purpose when used in a manner consistent with AS1720.1 or AS1684.

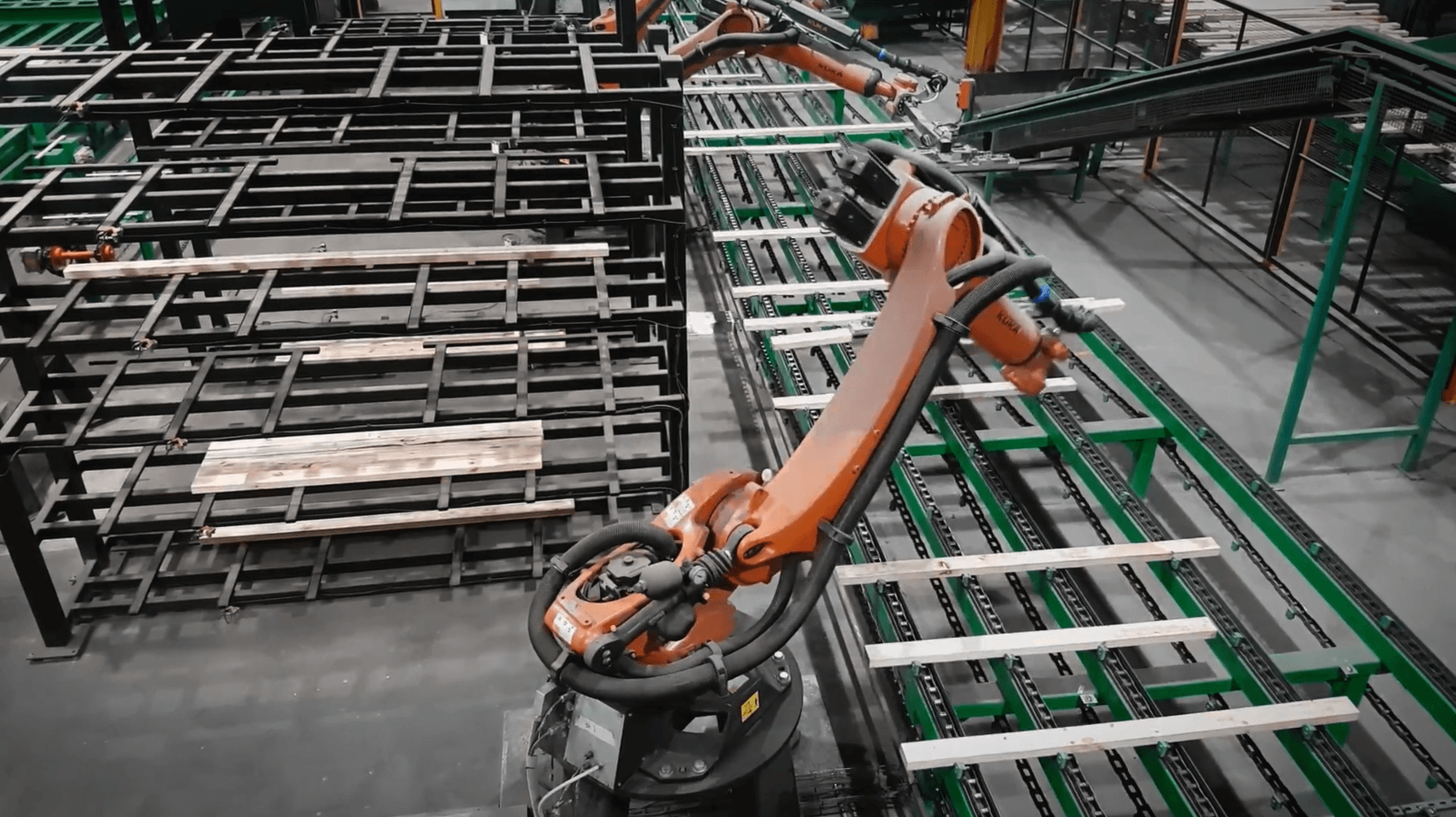

Machine Graded Pine (MGP) timber products are well known and understood in the Australian market and consumers can have confidence about the veracity of the claims made on these products if that timber is produced in sawmills that use a ‘qualified’ MGP grading method. Suppliers can’t just stamp timber as being MGP. Having a qualified grading method requires significant investment in grading equipment and initial destructive testing of products to confirm structural properties. Once the grading method is qualified, there is a requirement for ongoing verification of timber product properties, and periodic evaluation of the grading method used.

Each piece of timber is passed through modern grading equipment including machine stress-graders, or state of the art scanning which measures the stiffness of the piece and uses correlations to predict its modulus of elasticity and strength in order to sort into a stress grade. The targets for modulus of elasticity and strength are carefully selected to control the other structural properties of the sorted timber (i.e. bending, tension, compression, and shear strength). Regular sampling and testing throughout a batch is used to verify that the sorted timber meets the stress grade applied.

Branding requirements for MGP timber under AS/NZS 1748, include a grade stamp applied to the timber after the machine stress grading process. Once the machine has sorted a piece of timber based on its physical properties, a grade stamp is applied which will enable all subsequent people in the marketing and distribution supply chain to identify the structural properties applicable to that piece of timber. It is the final printed grade mark that indicates the grade of the whole piece of timber, such as a laser-printed mark at regular intervals.

Structural timber products sold in the Australian market (e.g., F-grades and MGP grades) must not be re-machined, ripped, or rebranded as either F-grade or MGP (excluding normal construction practices), unless the product is re-graded by a responsible entity using a machine stress grading method meeting the requirements of AS/NZS 1748 series. If a product is docked, the grade given to the stick at the time of production cannot be re-labelled as a higher grade. Any paint marks on MGP timber are for internal mill grading only and do not indicate any grade to the user.

The user must abide by the written grade detailed within the Brand printed on the stick at the time of production as the only grade descriptor. It should be noted that visual grading of timber is not an acceptable method to designate or re-designate timber as MGP. MGP grades can only be given to timber that has been machine graded in accordance with AS/NZS 1748. Re-branding of timber by other methods, or subsequent supply or use of MGP graded by a non-legitimate method, may be in breach of building material legislation in some States, and potentially carries significant penalties to the responsible entity that is undertaking those activities and making those claims.

How to read a structural timber brand

Learn how to read the brands on your timber. Each brand must contain:

- Producer name or mill code

- Standard (e.g., AS/NZS1748 or AS 2858)

- Grade (e.g., MGP10 in the image above)

- Moisture status (e.g., Seasoned or can be abbreviated to “S”)

It should also include information to allow traceability back to a production run (such as, date, time, or individual piece number).

How can fabricators be confident they are using timber that meets the Australian Standards?

Fabricators do need to ask several questions of their suppliers to ensure they have done reasonable due diligence checks on the timber. If a supplier cannot get answers to these questions from the manufacturer, it throws up questions about whether the timber meets Australian Standards.

Firstly, is the timber visually or machine graded? If visually graded, it is not MGP. F-graded timber can be either machine or visually graded, but the correct standard for visually graded F grades is AS2858, not AS/NZS1748.

Secondly, what evidence do they have that the verification requirements of AS/NZS1748.1 have been met? The best way to validate this it to ask for evidence of independent, third-party certification.

Evidence of Certification

If F grades or MGP grades are sold as meeting AS/NZS1748, the best way to validate this claim is to ask for evidence of independent, third-party certification. If the supplier is certified, ask where this certification can be confirmed.

Alternate evidence of conformance for non-certified suppliers

For non-certified suppliers, additional due diligence is required to ensure they have met the requirements of AS/NZS1748.1.

Alternate Evidence of Qualification

Non-certified suppliers should be able to provide one of the following:

a) A copy of the report qualifying the grading method to AS/NZS1748.2. This report is a requirement for compliance with the standard.

OR

b) Evidence of compliance with Appendix A of AS/NZS 1748.2 which includes:

i. That the grading method relies primarily on the use of non-destructive bending type stress grading equipment.

AND

ii. An initial evaluation of characteristic properties listed for the grade in AS1720.1 has taken place, either in isolation or as part of an industry in-grade testing program.

AND

iii. That this initial evaluation had been completed prior to 24/02/2011.

Alternate Evidence of Ongoing Validation

Regardless of which qualification method is used, non-certified suppliers should also be able to provide the following evidence.

a) The results of the in-grade determination of characteristic properties when tested and analysed in accordance with

AS/NZS4063. The properties must include MOE, bending, tension, compression, and shear strengths. Samples for

testing of in-grade properties must be representative of the variety of resource that the timber is produced from.

AND

b) The most recent annual verification check on the grading system. As this is a requirement of the standard, all legitimate producers will have this for one size/grade combination each year.

For MGP timber, EWPAA provides the following advice on conformance in Australia and what timber buyers should look for in terms of their own due diligence when choosing their MGP suppliers. The exert below on Certification can be found here.

Our Principal Partners