This piece was written and provided by FTMA Supporting Partner, Baumann Sideloaders Australia.

Efficiency gains are the new frontier in driving down costs in the frame and truss sector. While the low hanging fruit in reduced cost has always been cheaper raw materials, labour costs, and real estate, there is not only a law of diminishing returns in these areas, but over the last few years they’ve actually gone the other way – with significant price increases in all three

Understandably the sector is now examining all aspects with an eye on finding “hidden savings” in order to remain competitive. One of the costs which has come under this microscope is the amount of time and space which is taken to load and dispatch jobs; essentially – to drive efficiencies in the loadout yard. As the Director of Baumann Sideloaders Australia, Craig Armstrong-Fray explains; “Every business owner I’m talking to has the same problem – how can I store more jobs in a smaller space, and how can I reduce the amount of time it takes to load up a truck and trailer?”

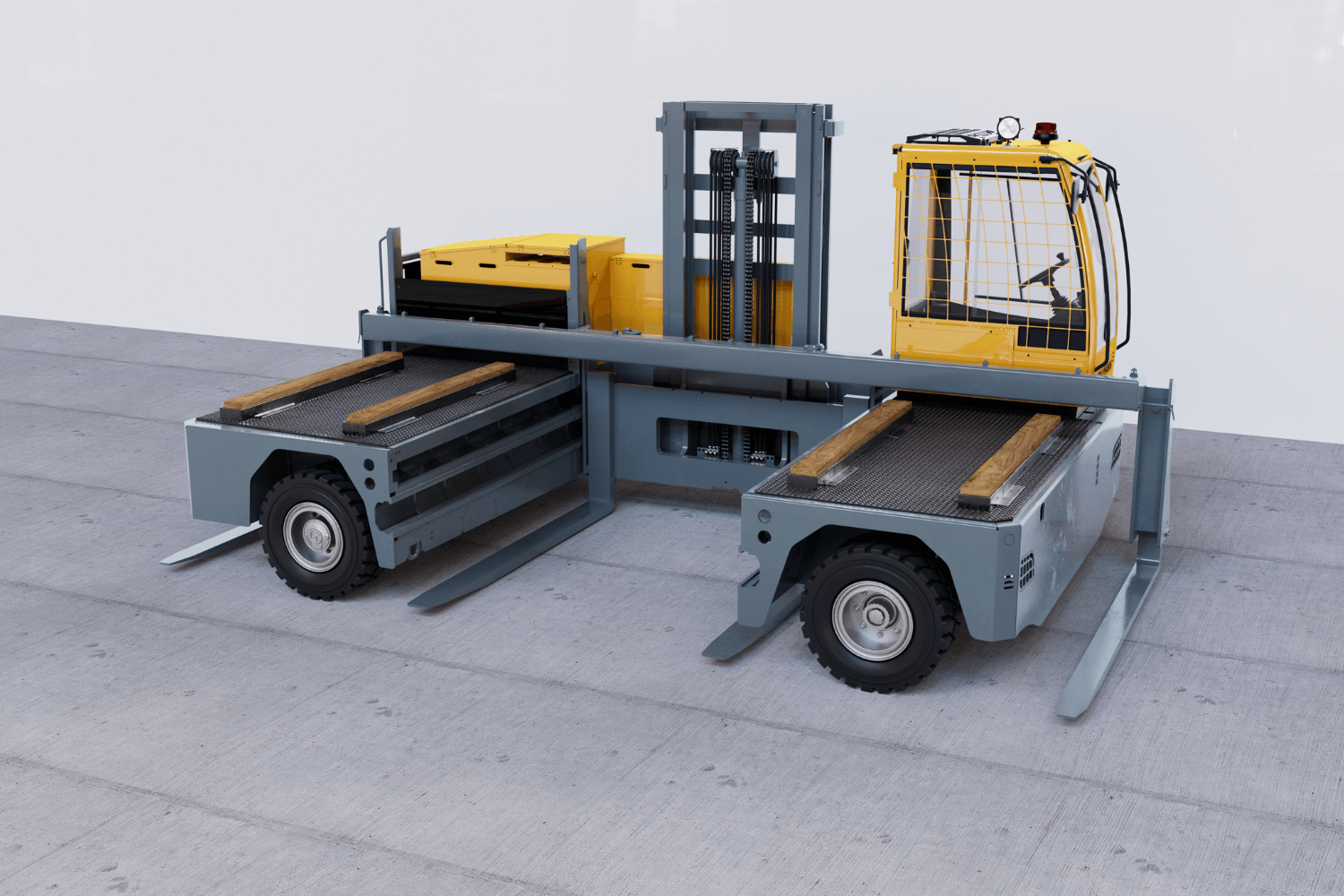

The answer usually lies in a combination of two factors; firstly, pre-packing complete job lots onto 12 metre long loading frames so the entire houselot can be lifted in one piece, and secondly, stacking these jobs in narrow aisles on cantilevered racking, using a Sideloader.

Conventional forklifts used in this role, often 12 or 16 tonners, are not only massively big due to the extended load centres of the loading frames (2400mm wide, therefore a 1200mm load centre), but they also need a large amount of space to carry the 12m long loads “across the chest”. Baumann Sideloaders can pick up the same load using a fraction of the space, being only a metre wider than the load itself. Baumann’s 8 and 10 ton capacity sideloaders can also be manufactured at a variety of load centres and deck widths, meaning that the operation doesn’t require a larger capacity forklift, just a smaller Baumann with a wider deck.

Aisle widths can be as small as 3.5m compared to around 16m for a conventional forklift. In addition to the massive space savings, there is a significant safety advantage by having long loads travelling lengthwise through the yard, all while being supported on the Baumann deck. Many operators shudder when they remember the all too familiar scenes of long lengths of timber and trusses being lifted by forklift high in the air to clear obstacles in the yard, teetering precariously on the narrow fork tines as the operator inches around a corner.

Baumann has been working closely with one of Australia’s leading proponents of loading frames to design a sideloader with the correct deck width and capacity to safely carry a complete houselot of frames and trusses. The goal is to reduce cost and save money by condensing storage space, and to turn trucks and trailers around in just a few minutes. Having multiple jobs packed and ready to go at a moment’s notice also assists in scheduling and logistics, further increasing efficiency.

“Best of all”, says Craig, “We can offer Baumann’s award-winning range of sideloaders on a variety of lease package options, as well as the option of electric drive on some models for our Carbon Warrior customers.”

If you’re interested in hearing more about this solution, email craig@baumann-sideloaders.com.au

Our Principal Partners