This piece was written and provided by FTMA Principal Partner, Pryda.

This year Pryda celebrated its 60th birthday. If you’re reading this article, chances are you already know a bit about Pryda, but there may be some things you didn’t know.

In this principal partner article, Pryda proudly shares some highlights of its 60 year journey from the perspectives of its own team, past and present.

Humble Beginnings

Established in Napier, New Zealand in 1964 by builder Ray Turner, Pryda began its journey as AR Turner & Company.

With a passion for solving problems, Ray designed and manufactured products such as angle braces and knuckle nailplates from his kitchen table. These remain best-selling and essential products today.

A key figure in the early days was Chris Rogers, who joined the company in 1975 and held several roles including Chief Engineer, General Manager and Managing Director.

“When I joined, there were 12 of us in the company,” says Chris.

“We were breaking new ground, with an incredible level of market and technological development during this period from very humble beginnings.”

One example of the technological advancement was Pryda being the first in Australia and New Zealand to introduce automated machinery with the Omni Computerised Saw, first adopted by Key Building Components (now Dahlsens) and MB Prefab (now Big River Group – Breakwater).

“Back in those days nobody had computerised saws, so economically it was easy to justify,” says Chris.

“It opened the floodgates, and we sold a dozen saws in the first 12 months!”

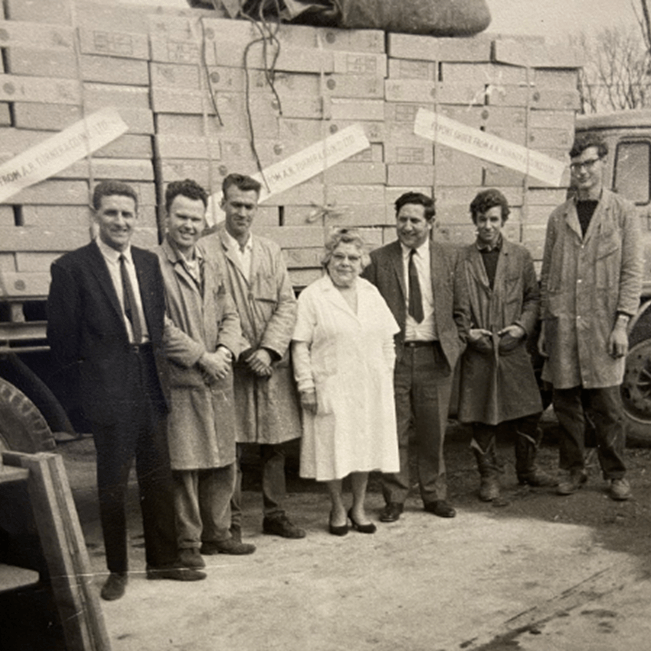

Ray Turner pictured 3rd from right next to his mother

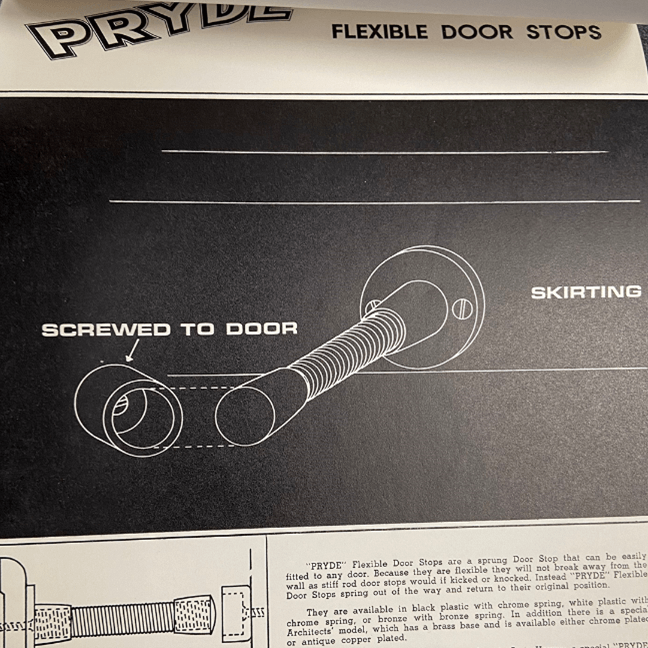

One of Ray’s earliest creations to receive a patent was Pryda Flexible Doorstops

A World First

There will be some fabricators who can still remember laying out timber on the floor, cutting the webs and doing the calculations by hand using a drawing board.

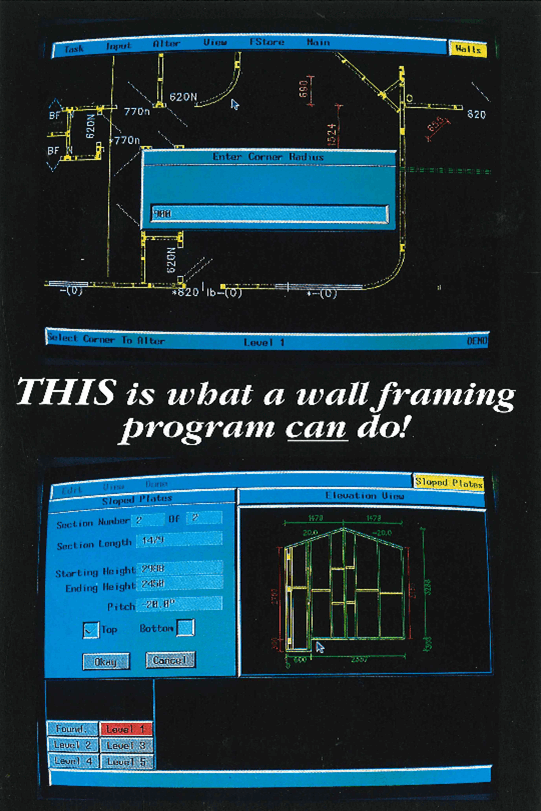

Pryda’s first wall detailing software, Computa-Wall, introduced in 1994 was ahead of its time, revolutionising the industry as the most powerful wall detailing software in the world, enabling users to see frames taking shape through data input. The software was also integrated with the production software Plant Net, streamlining the production processes in factories.

Greg Hay joined Pryda in 1995 as a detailer, providing support to fabricators by creating truss designs that were beyond the capabilities of the software at the time

“Over the years, software advancements have been remarkable, with one of the most significant improvements being the introduction of 3D views in the mid-2000s,” says Greg.

“This not only benefited fabricators but also their customers.” said Greg.

Pryda Computa-Wall eventually evolved into Pryda Build i with Pryda also a pioneer in introducing an integrated roof, floor, and wall design software package for fabricators.

Home Base

For more than 40 years Pryda’s manufacturing has remained at Healey Road, in Melbourne’s outer east.

It’s where Pryda manufactures all nailplates and bracing and continues with local production of a large proportion of other products in Australia and New Zealand.

Operations Manager, Andrew Skerritt has been with Pryda for 25 years and believes in the benefits of manufacturing locally.

“Nearly everything that goes out our door is sourced and made in Australia / New Zealand before it reaches our customers,” says Andrew.

“From a quality assurance and continuity of supply perspective, to have that stability is one of the things that sets us apart from other businesses.”

The construction of the Healey Road facility. Chris Rogers pictured right.

Andrew Skerritt pictured right, during his early days at Pryda

While the Pryda team is now dispersed all over Australia and New Zealand and remote working commonplace, stepping into the Healey Road facility still feels special.

“For many people, this business is their life”, says Andrew.

“Healey Road is a little bit of an oasis where it’s like being part of a family. You can always buy new machinery and tools but it’s the people that make it all come together. We’re still lucky to have that in our entire business.”

Exploring New Frontiers

As Pryda continued to grow, it ventured into new markets, most notably in Malaysia, Thailand and Indonesia.

Each country presented unique challenges from navigating language barriers, understanding cultural nuances, and most significantly, adapting to different construction practices.

The Thailand venture holds particularly fond memories for Bernard Kennelly, Marketing Development Engineer and one of Pryda’s longest serving team members.

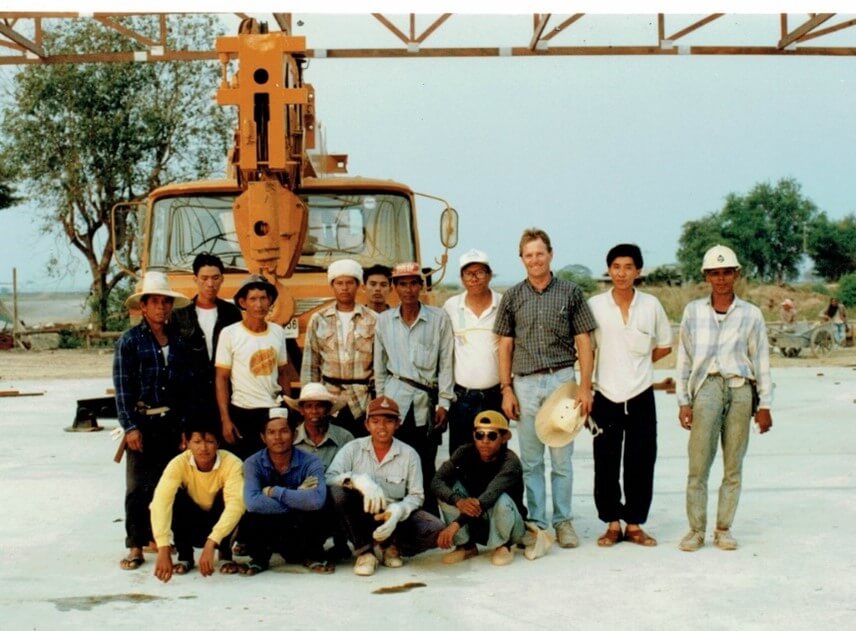

Bernard dedicated three years of his career in Thailand, helping to open the first office in Chiang Mai in 1991 and introducing timber trusses and nailplate technology to the local building construction industry.

Bernard Kennelly pictured top row 3rd from right

To meet the rapidly growing housing demand, the Pryda team and local fabricators started building temporary truss plants.

“These mobile plants were designed for effective transportation between sites by just a crane while enabling workers to stay dry and out of the sun,” says Bernard.

Despite the resource constraints, the team improvised with pallets to facilitate the installation of the portal gantry press. Roof trusses for the factory were then made in the jig shortly before being assembled into braced bays and carefully lifted into place. Each truss required the effort of 23 people to lift it off the jig!

Working Safer, Faster, Easier

A major milestone in Pryda’s history was the acquisition by global Fortune 200 company, Illinois Tool Works (ITW) in 2003.

The change of ownership had a transformative effect for Pryda with its decentralised and entrepreneurial culture proving to be a great fit and fueling further growth.

Maurie Anglin (General Manager Pryda) pictured left with Michael Davies (Group Vice President ITW Construction Asia Pacific)

At ITW, a company with more than 19,000 patents, innovation is key for growth. From its early days creating inventions in Ray’s kitchen and throughout its 60 year journey, Pryda has maintained an unrelenting commitment to providing safer, faster, easier construction solutions.

As with all Pryda’s innovations, the genesis of SpeedTruss™ was based on solving common pain points.

“One of the biggest issues on site is the finish of the roof truss system,” says Nicky Woodward, Pryda Software Product Owner and part of the team responsible for bringing SpeedTruss to market.

Nearly a decade on, the SpeedTruss™ roof installation system is a staple across building sites all over the country and remains the fastest, most controlled method of truss installation in the market.

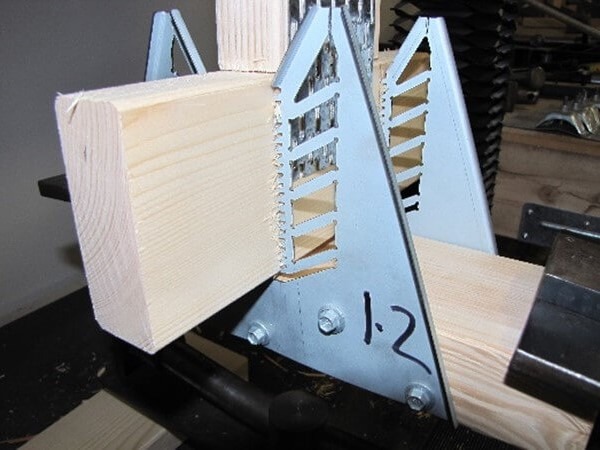

At MCM Frame and Truss (NSW) for SpeedTruss trials in 2015

Early concept

The development journey considered every part of the truss installation process, including integration with the software, working with fabricators to understand their manufacturing capabilities, educating inspectors and lots of testing!

“It was about bringing along everyone on the journey and showing them the benefits,” says Nicky.

“When they saw the speed of installation, the accuracy and the reductions in call backs to site they were convinced it was a winner. Ultimately for the builders it means they can complete more jobs and get more work.”

At the 2024 National FTMA Conference, Pryda contributed an artwork titled “Connections” marking our 60-year anniversary.

The mosaic is a joyous celebration of our connections far and wide. It represents our connection to our history, our connections to our local communities in which we serve and operate, our connections to our families and home lives, our partnerships with our customers, our contributions to the industry and our firm commitment to advancing timber frame construction.

Our Principal Partners